Home

About us

News

Products

Service network

Download

Online order

Contact us

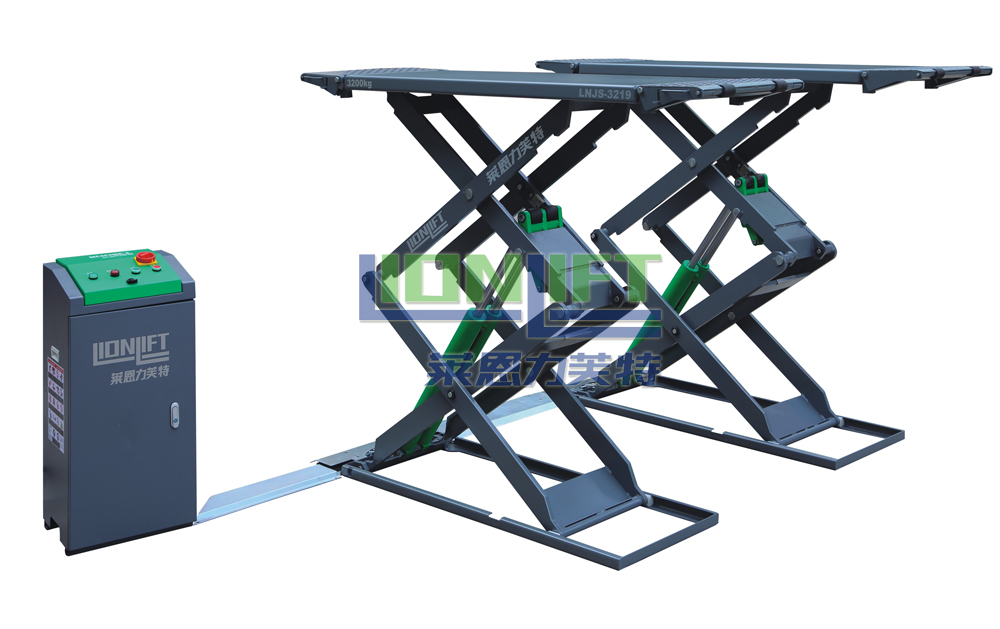

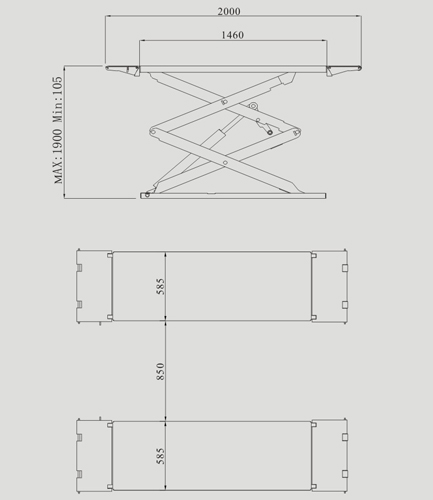

1.With an ultra-low height of 105mm’ the lift adapts to various vehicles with low chassis. The machine can be installed directly on ground.

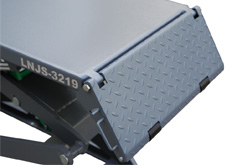

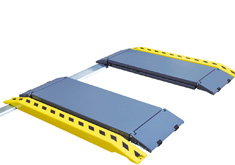

2.The load bearing approach bridge can extend the platform to 2000mm’ which suites for various vehicles including SUV and business automobiles.

3.With Italy technology double tandem synchronous hydraulic system’ cylinders are balanced automatically’ so there is no need to fill oil manually’ which ensures synchronous lifts of platforms.

4.Imported Italy oil seal prolongs the life of the cylinder.

5.Explosion-proof valves for oil pipes and self-lock function of dual circuit hydraulic systems ensures safety of people and vehicles.

6.Integrated PLC computer controller features self-testing function’ offering guidance in eliminating faults and ensure safe voltage.

7.Maximum and minimum cylinder protection systems for both benches generate maximum and minimum limits to prevent feet injuries. Buzzing alarms during machine descending help ensure safety of operators and people around.

8.Rollover-preventing devices are installed on both benches’ so when a height variance happens’ the machine stops automatically to ensure safety.

9.The surface adopts the static powder coating’ so it is of anti-errosion’ good adhesion and high hardness.

10.Double deck steel oil pipe achieves good explosion-proof performance.

11.With high quality international-standard steel as raw materials’ the equipment has bigger self-weight compared to homogeneous ones. Holes of front arms are made with CNC sawing machine to ensure same heights.

|