Home

About us

News

Products

Service network

Download

Online order

Contact us

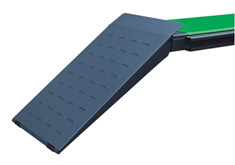

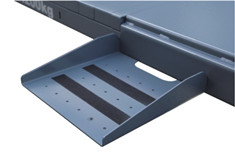

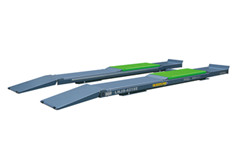

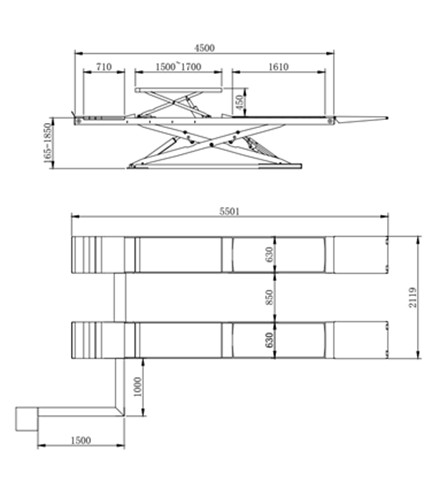

1.Super low platforms(165mm minimum height)and ramps meet various chassis height of vehicles’small space to take and installed directly on the ground.

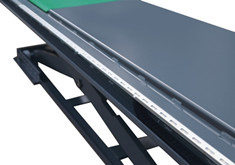

2.6mm whole board laser cutting’ whole board bending benches extend the platform to 4500mm to match various vehicles.

3.Double tandem synchronous balanced cylinders and six cylinders driving ensures synchronous lifting of platforms’the 4.2T lifting capacity can match various vehicles repair requirement.

4.Platform length of secondary lift can be extended to 1800mm’ ramp is enougt for all cars even SUVs and business vehicles.

5.Mechanical safe lock’ explosion -proof valves and self-lock of hydraulic systems ensure a safe work.

6.Integrated PLC computer controller features self-testing function’ offering guidance in eliminating faults and ensure safe voltage.

7.Imported oil seals from Italy flat combination valve block structure and triplr oil circuits can also be quickly leveling’avoiding oil leakage inside.

8.Maximum limit mitigates abrasion of cylinders and preventsmachine overloading.

9.Decline buzzing alert and light alert reduce the possibility of safety accidents.

10.The surface adopts the shot blasting’ degreasing’ phosphating’static powder coating’ so it is of anti-erosion’ good adhesion and high hardness.

11.High quality international-standard steel as raw materials’ the lift is heavier.Holes of front arms are made with CNC sawing machine to ensure the consonant quality.

12.120% dynamic loading test and 150% static loading test comply with the CE standard.

|