Home

About us

News

Products

Service network

Download

Online order

Contact us

1.Recess mounted installation occupies less space. A lift capacity of 4.0T can meet requirements of various vehicles.

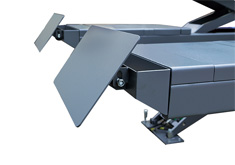

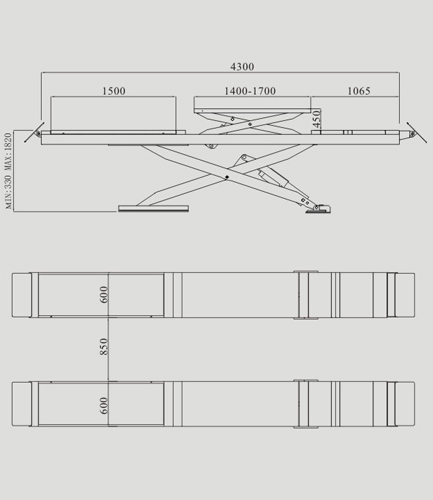

2.Benches of 6mm seamless square steel tubes adapt to various vehicles and there are also platforms of 4500mm as an alternative.

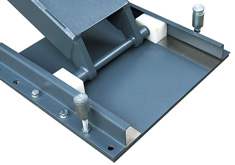

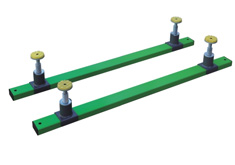

3.Movable sub-machine platform may extend its length to 1800mm’ with side slide clamps’ adapting to vehicles of various wheelbases. The lift can be used for SUV and business vehicles.

4.The use of mechanical safe lock’ explosion -proof valves and self-lock of hydraulic systems ensure a safe work.

5.Integrated PLC computer controller features self-testing function’ offering guidance in eliminating faults and ensure safe voltage.

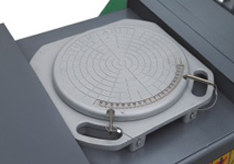

6.Tandem synchronous cylinder ensures sychronous bench lifting’ which not only prevent rollovers of vehicles’ but also provide a precisely level surface for wheel alignment. It adapts to different types of wheel alignment machines.

7.Imported oil seals from Italy prolongs the life of the cylinder. Imported manual oil-input valves from Italy avoid oil leakage inside’ and no need to fill oil frequently for rebalance.

8.Maximum limit mitigates abrasion of hydro-cylinder and overload of hydraulic systems’ which prolongs usage life of the machine.

9.Sound and light alarms during the descending ensures safety.

10.The surface adopts the static powder coating’ so it is of anti-erosion’ good adhesion and high hardness.

11.Double deck steel oil pipe achieves good anti-explosion performance.

12.With high quality international-standard steel as raw materials’ the equipment has bigger self-weight compared to homogeneous ones. Holes of front arms are made with CNC sawing machine to ensure same heights.

13、120%dynamic loading test and 150% static loading test comply with CE standard

|